WHY HARDWOOD FLOORING?

For added value, beauty & health benefits, many consumers are turning to wood flooring

Easy maintenance, longer lasting finishes, exotic species, style versatility & competitive prices are some of the reasons for the growing popularity of wood. Wood floors come in a variety of styles to meet the demands of today’s busy lifestyles. From factory finished, unfinished & solid to engineered, strip, plank, parquet, & acrylic impregnated. Choose the wood flooring that works for you based on decorating style & the area that you live in.

Need A Sample? Stop By Today!

VISIT US!PROFESSIONAL SERVICE

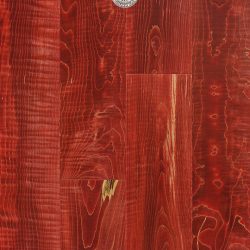

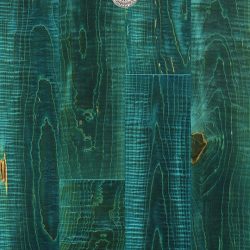

Wood floors come in a rainbow of colors to fit any decor, Unique, one of a kind looks can be achieved with custom stains and finishes. According to National Wood Flooring Association, wood floors come in more than 50 species, both domestic and exotic spanning the spectrum of colors options, hardness and price ranges.

Environmental concerns should also be a consideration when it comes to choosing wood flooring over other options. There are estimated to be 60 million Americans suffering from allergies, many people are converting to “healthy homes” or asking that non-allergenic products be specified. Doctors often recommend hardwood floors because they trap less animal dander, dust, pollen, mites, and mold-all of which can trigger respiratory problems. Natural hardwood floors reportedly make it easier to reduce home allergens.

TYPES OF WOOD FLOORING

Resale home value increases in homes decorated with hardwood. Realtors’ survey finds that homes with wood floors sell faster than dwellings with other types of flooring. Wood floors have a projected life of 50 to 80 years, resulting in long-lasting value.

Hardwood floors can be installed in virtually any room of the house. A variety of installation options & types are available, depending on whether the floor will be installed on, above or below grade. For example, engineered products, which are inherently dimensionally stable, are a better choice for basement than solid hardwood.

Colors: Wood floors come in a rainbow of colors to fit any decor, unique, one of a kind looks can be achieved with custom stains & finishes.

Species: Today’s wood flooring comes in more than 50 species domestic & exotic spanning the spectrum of colors, hardness & price ranges.

Grades: The appearance of wood determines its grade. All grades are equally strong & serviceable, but each affords a different look.

Clear wood is free of defects, though it may have minor imperfections.

Select wood is almost clear but contains some natural characteristics such as knots and color variation.

Common wood ( No 1 or No 2 ) has more natural characteristics such as knots & color variations than either clear or select grades & often is chosen because of these natural features & the character they bring to a room. No 1 Common has a variegated appearance, light & dark colors, knots, flags & wormholes. No 2 Common is rustic in appearance & emphasizes all wood characteristic of species.

First Grade wood has the best appearance, natural color variations & limited marks. Second-grade wood is variegated in appearance with very sound wood characteristics of species. Third-grade wood is rustic in appearance allowing all characteristic of species.

| Bruce | Anderson Hardwood Flooring |

| Armstrong Flooring | Berry Hard Surfaces |

| Bruce Wood Flooring | Carolina Homes |

| Ferma Wood Flooring | Harbor Woods |

| Homers Woods | Johnsonite Vinyl |

| Kardean Luxury Vinyl | Kraus flooring |

| Max Windsor Woods | Mercier Hardwood Flooring |

| Mirage Wood Flooring | Shaw Hard Surfaces |

| Tarkett Vinyl | Tudor Flooring |

| Nustair Staircase Replacement |

TYPES OF WOOD FLOORING

The angle at which a board is cut determines how the finished products look. Wood flooring is either Plainsawn, Quatersawn, or Riftsawn.

- Plainsawn is the most common cut. The board contains more variations than the other two cuts because grain patterns from the growth rings are more obvious.

- Quatersawn produces less boards per foot than Plainsawn & is therefore more expensive. Quatersawn products woods twists & cups less & wear more evenly.

- Riftsawn is similar to Quatersawing but the cut is made slightly on a different angle.

Solid Wood: When manufacturer talks about a solid floor, they are referring to a 3/4 inch thick piece of solid wood. Although solid floors are available with a factory finish, they can also be finished on the job site. They can be installed on or above grade & not on a slab. The wood is generally nailed to a plywood subfloor.

One thing to keep in mind is that solid floors may not perform well in an area of high humidity or areas with large temperature changes. Because solid flooring is a 3/4 inch thick section of a tree, it responds to water & moisture like a tree. If the air is hot & humid, the floor will soak up moisture causing it to swell. When the air dries out, the floor will shrink, leaving gaps in between the boards. The wider the boards the bigger the gaps & more likely it will “cup”. So most solid wood floors are either 2 1/4 inches wide or 31/4 inches wide. For this reason, solid wood flooring is most common in areas with low humidity such as the North East & Midwest. One of the reasons why people generally like solid hard wood floors is because they are traditional & can be sanded many times. If they are finished on the job site, they are relatively easy to sand & refinish. Also it is possible to achieve a true square edge profile with sand & finish floor versus pre-finished ones. On the downside, is a solid wood floor is finished on job site; it can be difficult to imagine a true color until the job is done. In addition, installation can take a longer time as each layer of finish must dry before the next coat is applied.

Engineered Wood: The PT boats that were used in World War II were actually constructed out of several layers of wood, with each graining facing in the opposite direction of the layer above or below it. It was this concept that gave birth to engineered wood flooring. To better understand this concept of cross-piled wood, let’s look at the basics. A tree uses its roots to take water from the ground and delivers it to the leaves using straw-like cells to move the water up to the trunk. These cells get plumper when they are full of water & shrink when they are dry. Just as these cells change with moisture in a tree, they will also change with moisture within a floor. By stacking veneers with these cells facing in opposing directions, no one layer can grow or shrink too much in any direction. Because engineered floors can handle a certain amount of moisture from the sub-floor, they can be installed anywhere in the house; on, above, or below grade, one concrete or plywood subfloors with glue, nail or even by floating.

Most engineered floors are finished at the factory, so they generally have aluminum oxide in the finish. Aluminum oxide is the hardest manmade crystal in the world & therefore adds years to the finish warranty. As for sanding and refinishing, an engineered floor can be sanded about twice depending on the thickness of the wear layer. The aluminum oxide, however, makes it very difficult to actually sand the finish off.

The Finishing Touch: Lasting beauty requires minimal care with today’s wood floor finishes. The most popular finishes today are surface-finishes because they are durable, water-resistant & require minimal maintenance. They most often are referred as polyurethanes & remain on the surface of the wood to form a protective coating. There are several types of surface finishes:

Oil-Modified finishes are easy to apply. It is solvent-based polyurethane that dries in about eight hours. This type of finish ambers slightly over time & is also very durable.

Moisture-Cured finishes are solvent based & more durable & more moisture resistant than other surface finishes. Moisture-Cured finishes are generally available in stain or gloss. These finishes are extremely difficult to apply, have a strong odor & are best left to the professionals.

Conversion Varnishes have an extremely strong odor & should be applied by the highly skilled flooring professionals.

Water-Based Finishes are clear, non-yellowing & very durable. They have a milder odor & dry in about two to three hours.

Penetrating Stain & Wax soaks into the pores of the wood & hardens to form a protective penetrating seal. The wax gives a low-gloss satin sheen. They are durable but will show spots from water & other contaminants. They are generally maintained with solvent-based waxes, buffing pastes or cleaning liquids (specially made for wax-finished wood floors).

Acrylic Impregnated Finishes are injected into the wood to create a super-hard, extremely durable floor. These finishes rarely are used in residential applications. They most often are used in very high traffic areas in commercial settings such as malls and restaurants.

INSTALLATION METHODS

Nail Down vs. Glue Down vs. Floating Application

When most people think about installing wood floors, they typically envision a hammer, nails & a lot of back-breaking work. There are, however, several options available & choosing one will depend on the flooring used, whether it is installed above or below grade & the subfloor material. Basically, there are three methods used to install wood floors: nail down, glue down & floating.

Nailing down wood floors is the most common installation method. The process involves nailing the flooring directly to a wood subfloor. Typically, the flooring is blind nailed through the tongue so the nails are not visible after installation. This method works for solid & engineered floors, but only for wood subfloors. Nailing schedules are critical to ensure quality installations. The National Wood Association Guidelines recommends fasteners be space 8 to 10 inches for solid flooring & 4 to 8 inches for engineered flooring. Using fewer fasteners could result in cracks or squeaks, while using more could result in split tongues.

The glue down method involves using adhesive to adhere the flooring to the subfloor. Adhesives work by creating a bond between the subfloor & the wood flooring through a chemical reaction process. While all adhesives work by changing chemically from a viscose liquid to a solid, they differ in the carrying agents or catalysts that activate them.

There are three types of wood flooring adhesives available today. They include water Based, solvent-based & moisture-curing. Because each type has different application, performance & VOC regulations.

Using this method, the flooring is neither nailed nor glued to the subfloor but floated above it. The flooring, usually engineered, is glued or clipped to itself, tongue to groove, & at end joints. This gives the floor stability without actually fastening it to the subfloor. This installation method is ideal over existing floors such as laminates, which can be difficult to remove.

Before beginning a floating installation, the installer must make sure the subfloor is dry & level any high or low spots. A moisture barrier underlayment will decrease any hollow sounding areas that could occur. The underlayment must wrap up the wall to completely encapsulate the flooring. Then, when the last board is installed the excess underlayment or padding can get trimmed off.

Note: For the best installation results, always read and follow the manufacturers’ recommendation.

Glossary of wood flooring terms:

Following is a partial list of terms associated with hardwood flooring that a retail salesperson or installer may come across and should have complete understanding.

ACRYLIC: The generic name for wood-plastic composites utilizing wood impregnated with acrylic monomers and polymerized within the wood cells by gamma irradiation. Some versions are cured by heat radiation.

AIR DRIED: wood that is dried by exposure to air in a yard or shed without artificial heat.

ALUMINUM OXIDE: Refers to one of the most durable finishes for wood flooring. It can only be factory-applied. This finish is highly abrasion resistant but slightly clouds the wood’s color and grain.

BOW: The distortion of lumber in which there is a deviation in a direction perpendicular to the flat face-from a straight line from end to end of the piece.

BURL: A swirl or twist of the grain of the wood that usually occurs near a knot but.

CARB: The California Air Resources Board a department of the California Environmental Protection Agency also the term used for the regulation passed by the board that puts highly restrictive limits on formaldehyde emissions in wood. It took effect Jan.1 and consists of two main phases that will be implemented through July 1, 2012.

COMPRESSION SET: Caused when wood absorbs excess moisture and expands so much that the cells along the edges of adjoining pieces in the floor are crushed. This causes them to lose resiliency and creates cracks when the floor returns to its normal moisture content.

CROWNING: A convex or crowned condition is the appearance of individual boards where the center of the board higher than the edges.

CUPPING: A concave or dished appearance of the individual board with the edges raised above the center.

DE-LAMINATION: The separation of layers in an engineered board through failure within the adhesive or at the bond between adhesive and wood.

DIMENSIONAL STABILITY: The ability to maintain the original intended

dimension little or no expansion and contraction when influenced by humidity swings.

Some species are more dimensionally stable than others. In addition, engineered flooring products are substantially more stable than their solid counterparts.